Collaborators

Project Brief

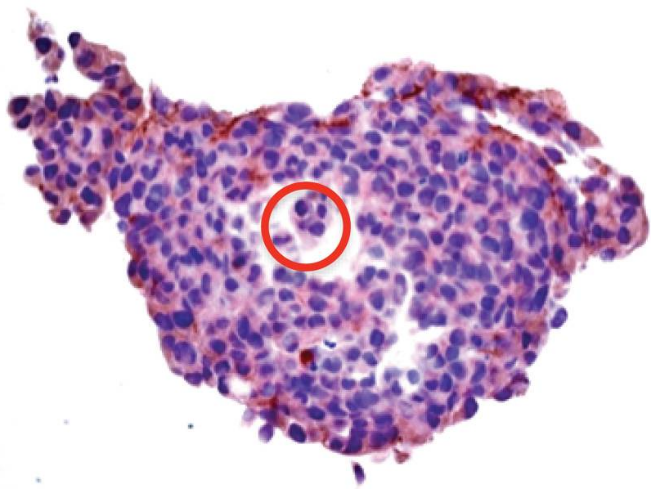

Studies evaluating potential chemotherapeutics and multi-drug resistance in cancer cells have been established using in vitro 2D culture and in vivo animal models. However, neither method accurately recapitulates human tissue or the course of tumorigenesis. 3D cell cultures better simulate the in vivo environment for tumor growth, but is currently limited by insufficient mass transport of oxygen due to a lack of vasculature.

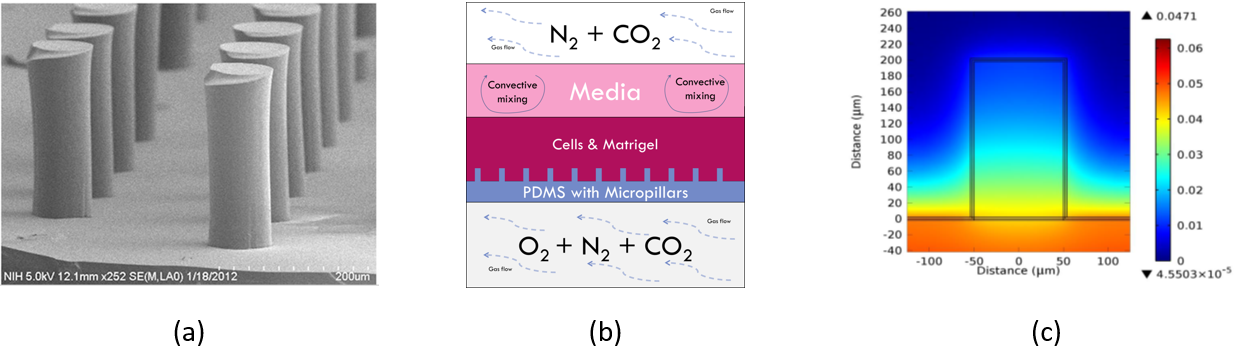

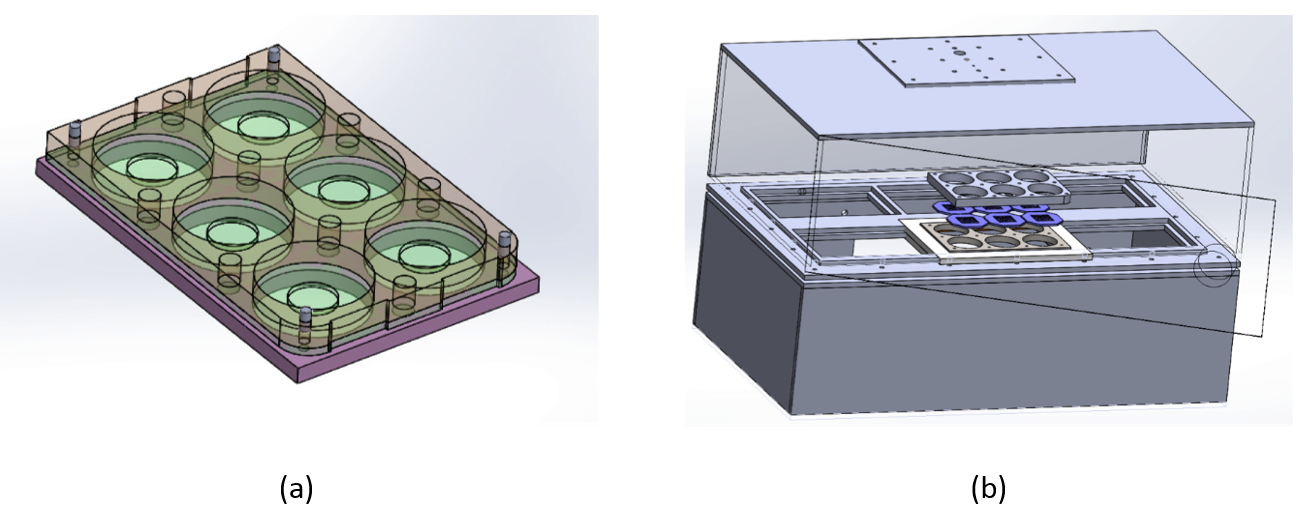

An interdisciplinary team from NCI, NIBIB, and CIT SPIS laboratories has developed microfabricated synthetic mimetics of vasculature to provide oxygen to 3D cultured tumors and other tissues. A second generation prototype, consisting of a bioreactor chamber system accommodating a six-well plate format, has been recently developed, undergone preliminary characterization, and tested under a limited number of cell culture conditions. The bioreactor setup allows for multiple 6-well plates increasing experimental throughput, and in particular: to enable multiple parallel culture conditions under controlled hypoxia and to expand the potential application of the system to a variety of problems, including drug-screening studies.

Tech Transfer

Patent application: Microfabricated Polymeric Silicone Hydrogel Vessel Mimetics