The BETA Center Makerspace offers the NIH research community access to various fabrication tools and equipment to help meet their needs. Through project consultation, workshops, and hands-on training, the Makerspace aims to help users build their confidence in operating available fabrication equipment to innovate and advance their research.

For more information about how to access and use the equipment please visit the Makerspace at Building 13 Room 3W31 or email us at BETACenterMakerspace@mail.nih.gov.

Fabrication Equipment

FDM (Fused Disposition Modeling) 3D Printers

Fused Disposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is a versatile 3D printing method that can be used from the prototyping phase up through final production, depending on the user’s needs. FDM 3D printers extrude a thermoplastic filament through a heated nozzle, depositing the material layer by layer to create a three-dimensional object. The Makerspace’s FDM 3D printers are capable of small- to large-scale prints using hard and rigid plastic materials.

| Model | Build volume | Z-layer height resolution | Materials |

| Bambu X1E FDM | 256 mm x 256 mm x 256 mm (10 in x 10 in x 10 in) | 0.08 mm, 0.16 mm, 0.2 mm, and 0.28 mm | Polylactic acid (PLA), polyethylene terephthalate glycol (PETG), polyvinyl alcohol (PVA, for support print only) |

| Modix BIG-120Z FDM | 600mm x 600mm x 1200mm (23.5 in x 23.5 in x 47 in) | 0.4 mm and 0.6 mm | Polylactic acid (PLA) and polyethylene terephthalate glycol (PETG) |

Resin 3D Printers

Stereolithography (SLA) or resin 3D printers are capable of printing with high resolution, producing smooth surfaces for prints requiring high precision and fine details. SLA 3D printers use lasers or LED screens to project UV light to cure liquid resin into a solid layer by layer. The Makerspace is suited with resin printers of two different print volumes, capable of printing with various materials, including biocompatible resin.

| Model | Build volume | Z-layer height resolution | Materials |

| Formlabs Form 4B | 200 mm x 125 mm x 210 mm (7.9 in x 4.9 in x 8.3 in) | 0.025 mm to 0.2 mm (depending on material) | BioMed Clear and BioMed Black |

| Formlabs Form 3L & 3BL | 335 mm x 200 mm x 320 mm (13.2 in x 7.9 in x 12.6 in) | 0.025 mm to 0.3 mm (depending on material) | Standard Gray, Standard Clear, BioMed Black, BioMed Clear, and BioMed Flex |

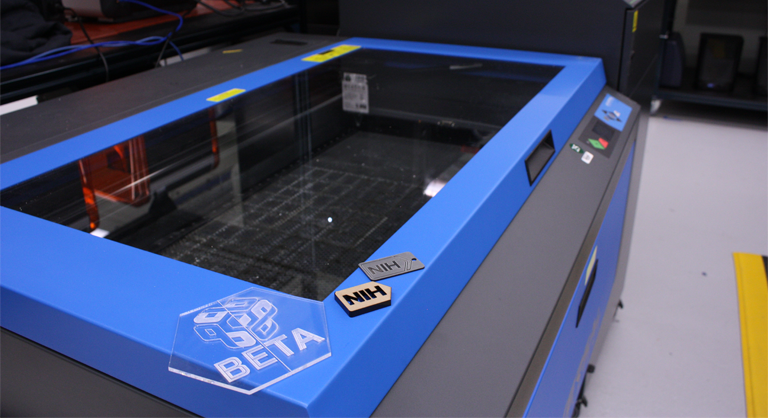

Laser Cutter

A laser cutter is an engraving and cutting machine that works by directing a high-powered laser onto a material’s surface and causing it to melt, vaporize, or burn away, resulting in a precise cut or engraving. The laser cutter reads vector image files. One of the greatest utilities of a laser cutter is to cut out the sides of boxes or enclosures of custom dimensions. The Makerspace’s specific model is a 150W CO2 laser cutter.

| Model | Work area dimensions | Maximum cut thickness | Materials |

| PLS3.150D Universal Laser Cutter | 813 mm x 457 mm (32 in x 18 in) | 0.25 in | Acrylic sheets |

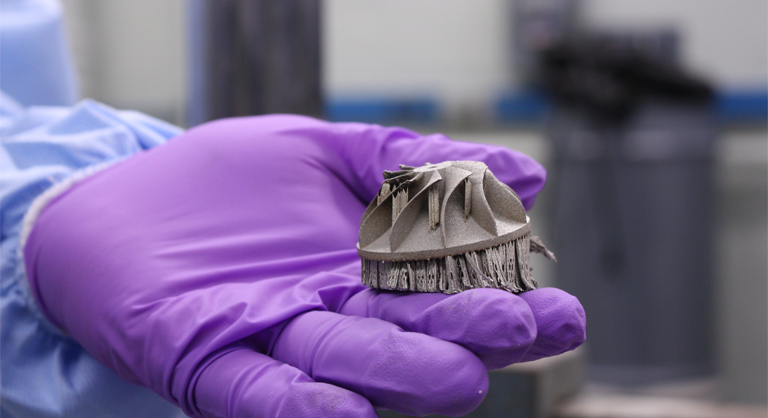

Metal 3D Printer and Dry Electropolisher

The most advanced 3D printer in the Makerspace is a metal 3D printer. This printer is capable of printing solid stainless steel or cobalt chrome parts in high resolution. Any interest in the metal 3D printer, please reach out to the Makerspace staff for a consultation. As a companion to the metal 3D printer, the Makerspace has a dry electropolisher. Unlike the traditional method of electropolishing, our machine uses a bead-like medium to smooth, deburr, and polish metal parts. The electropolisher can be used to finish metal 3D printed and non-3D printed metal parts.

| Model | Print/work volume | Z-layer height resolution | Materials |

| Xact XM200G metal 3D printer | 150 mm x 150 mm x 150 mm (5.9 in x 5.9 in x 5.9 in) | 0.02 mm to 0.1 mm | 316 Stainless Steel and Cobalt Chrome |

| Dry electropolisher | 180 mm (in diameter) x 80 mm | N/A | Most metals, except aluminum |

Other Equipment and Tools

To complement its larger equipment, the BETA Center Makerspace also provides access to a variety of hand and power tools, electronic test equipment, a UV curing system, and more.